1960s Cranvel Wombat backhoe

Taking on the 20 acre property in 2019, I really needed a digger, a workhorse. I had the tractors (1950 and 1963), but they can't dig!

And it had to be cheap, and it had to be a classic.

Enter the Cranvel Wombat, that had languished in a nearby shed (in Maryborough, Vic) for some 35 years. The previous owner (deceased) had used the Cranvel on his property to build dams and other earthworks, but mainly for digging for gold!

I was assured the old digger would have been running perfectly when it was last put away in the shed, but that was quite some time ago. The hydraulic hoses were obviously in very poor condition, and hand cranking the rope-start pulley showed the original Wisconsin THD twin cylinder air-cooled petrol had no compression, but I decided to take the gamble, and agreed to the asking price. See the pics below for the unfolding story, and for videos of it operating again in early 2023, see the YouTube clips at https://youtu.be/Enx9mDVhf0w and https://youtu.be/HWFLs39XjyQ .

↑After a lot of

winching, the very limp Cranvel eventually made it to its new home on the

trusty Isuzu.

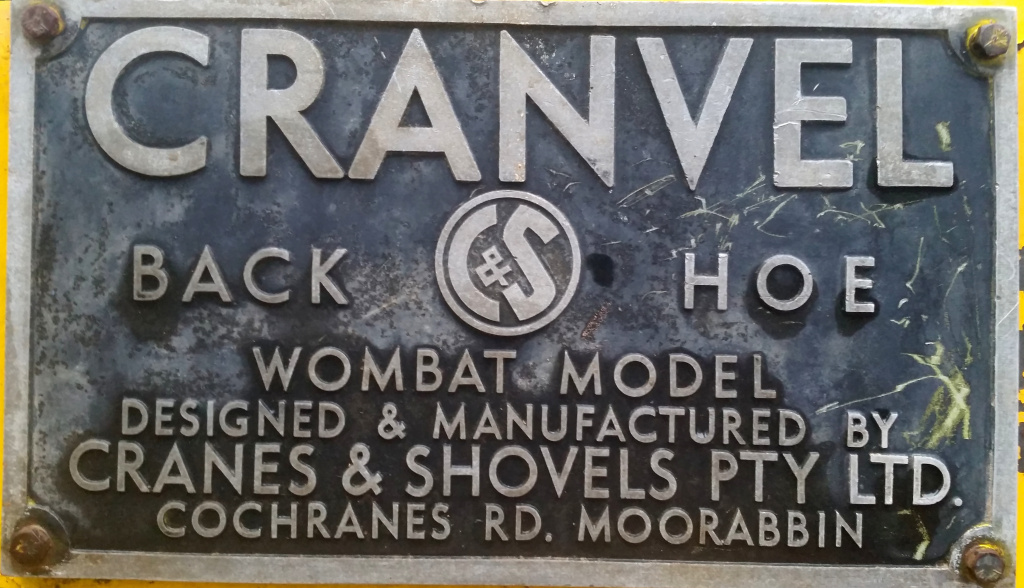

↑The original

plates.

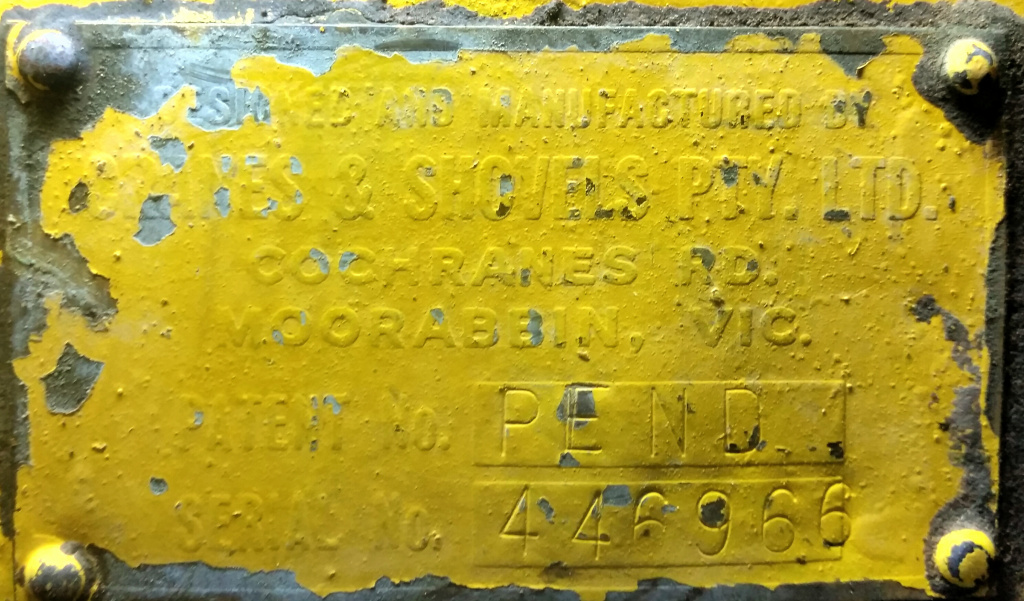

The original wheels, early Holden, were quite badly bent and rusted, so I decided to have a bit of fun, as well as being slightly sensible, and source a set of early Australian-made, Holden jellybean alloy wheels. These would give a wider footprint in soft conditions, better load capacity, and better traction, plus be a humorous 'modification'.

↑...so I purchased

these.

↑The Cranvel on tow behind

the Land Rover. This is how they used

to be taken from job to job back in the 1960s by any self-respecting plumber

or gravedigger!

↑The Cranvel gets

towed into the workshop for necessary work to be done.

↑The old hoses were

certainly not to be trusted! However, all field serviceable fittings, so the

search was on for the correct hose.

Easier said than done! The size was long obsolete, and impossible to find. Finally, my son David came to the rescue through his suppliers for his mechanical repair business, Rote Repairs. Several years' worth of birthday and Xmas presents covered, as it wasn't cheap!

↑They came up a treat,

though.

↑Next challenge was

to remove the cylinder head to allow valves to be relapped. One bolt snapped

straight off, despite all precautions, and proved to be a real challenge for

the next day or so! I tried everything; heat, penetraing oil, shock, welding

on a nut, etc etc, but the bolt had long become part of the head, so in the

end I carefully ground the bolt flat to the head surface, carefully

centrepunched it...

↑...and drilled it

out.

↑I then retapped the

thread...

↑...and finally, all

as good as new! Bores, pistons (both 40 thou oversize and showing no wear,

so a recent recondition), valves and valve seats were all perfect so a light

lapping of the valves into their seats was all that was needed to get

compression back to perfect.

↑Feb 8 2023 the Cranvel

Wombat fires up for the first time in almost 40 years!

↑the brakes had

clearly not functioned for at least 40 years, probably 50 or more. But it

was dangerous to use on slopes as it was, so the whole (early Holden) system

was removed, and totally renewed. The previous owner had used hydraulic

fluid in the system, so everything rubber-based was swelled and ruined.

Brand new master and slave cylinders and brake shoes were purchased, and the

almost toxic drums given a thorough cleaning! Also made up some new

double-flared steel brake lines, and installed it all. I can now work safely

on slopes!

↑the slew

ram was just too rusted and the clevis thread too worn to ignore, so a new

shaft was made up by Andrew at Hydrau Tech in Ballarat. New seals in this

ram and the stick arm ram, plus new O-rings in all the control valves,

stemmed the alarming leakage rate of hydraulic fluid!