1962 Fiat 500 D - engine rebuild

Damage to the head and pistons was extensive following the catastrophic overheating caused by incompetent welding by a previous 'restorer' (see here for details).

The fact that the car had its original engine was of paramount importance, and made the damage all the more tragic. Many 'suicide door' D models now on the roads have had later engines fitted, but I was determined to keep the car original. Heads are relatively easy to obtain for all subsequent Fiat 500 and 126 models, but unfortunately this does not apply to the 'D' engine. I searched widely all over the world for a suitable replacement, but came up with absolutely nothing.

Living in northern, rural Victoria, Australia, I had earlier learned of the extraordinary skills of the local engineers, who can turn their skills to repairing almost anything. Farm equipment is crucial to the local economy, and any repairs need to be effective and reliable. I had previously had some very challenging work done to Mercedes cylinder heads by a workshop run by a relatively young but extremely passionate and skilled man in Swan Hill, Victoria, so I took my ruined Fiat heads to him for appraisal.

Heath O'Brien at O'Brien Automotive Machining Services gave me a fairly positive prognosis for the head, without guaranteeing success. He also informed me he was moving the business closer to me, to Kerang, which was about half the distance for me (100km return) than his Swan Hill location.

There were many fragments of piston ring embedded in the damaged area, and the damage was quite deep and extensive. Cleaning was crucial to the success of subsequent rebuilding of the combustion chamber by welding, and the danger of distortion and cracking couldn't be ignored. A quote was given that I considered totally reasonable, so I gave Heath the go-ahead.

The results were simply stunning when I picked up the finished head from Heath's new Kerang premises, and further cement my faith in the quite extraordinary skills of Heath and his employees at O'Brien A.M.S. Thanks also to Trevor McIntosh (Pyramid Hill Mechanical and Welding) for his help in correctly shaping the combustion chambers.

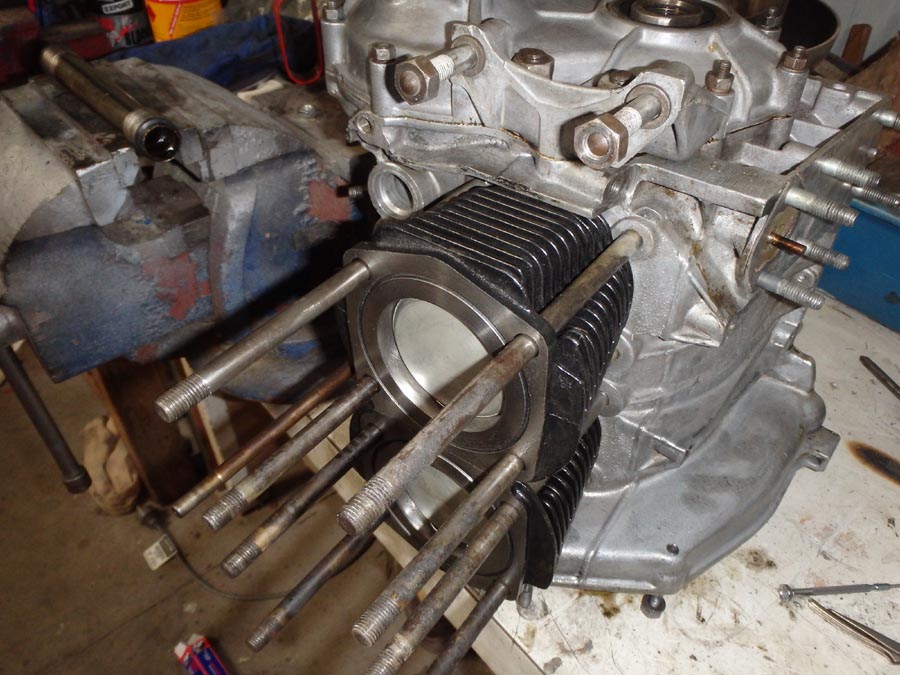

New pistons, barrels and rings and many other parts were sourced from Germany, while the majority of other parts came from Italy (many, many parts ended up being needed to either replace incorrect, missing or extremely worn parts for the exterior, interior, electricals and other mechanicals of this car, which was supposedly fully restored when purchased).

New barrels and pistons fitted.

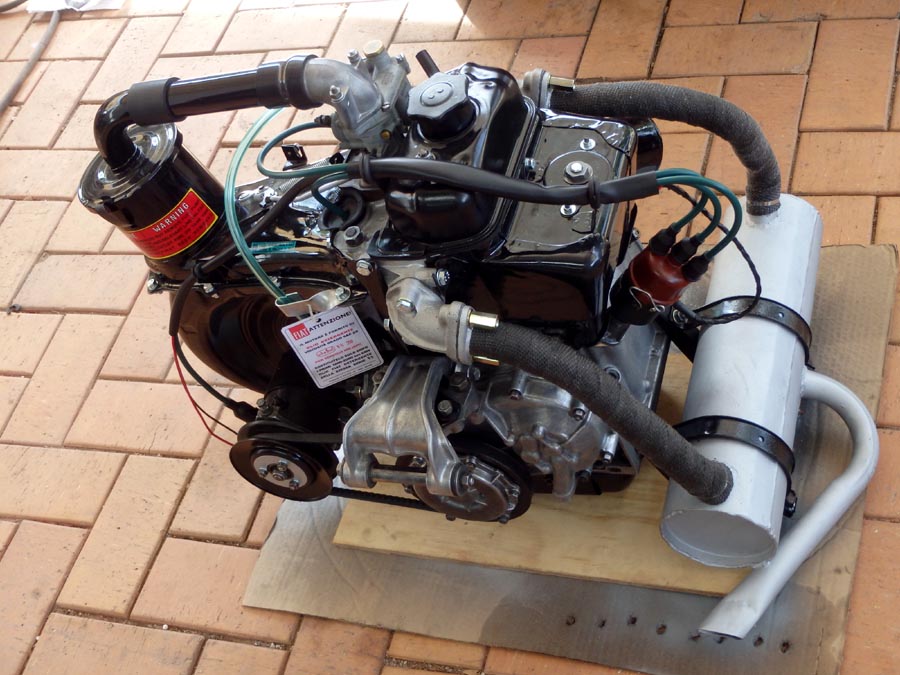

Pushrod tubes were expanded and fitted with new seals.

The repaired and carefully rewelded 'tinware' is refitted, along with a new cooling fan to replace the bent, totally worn out original which should never have been refitted by the previous rebuilder.

More cooling shrouding 'tinware' is fitted, along with a new thermostat carefully adjusted using a heat gun and thermocouple thermometer. The petrol pump was refitted as removed, but is about to be rotated 60 degrees to the correct location.

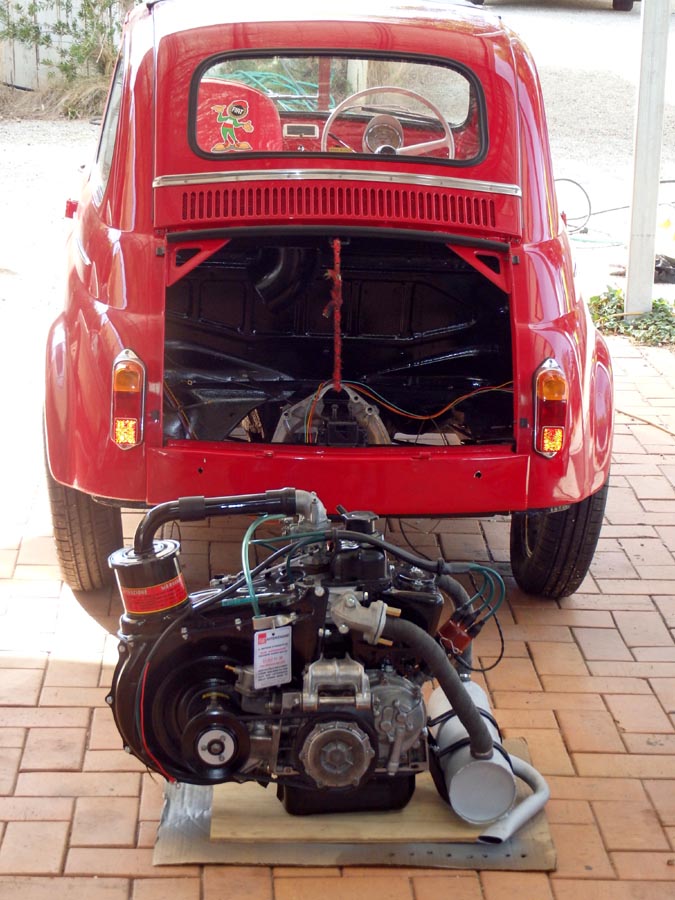

The engine is finally ready for refitting into the refurbished engine bay.