1964 PEUGEOT 403B

I've been a fan of pre-505 Peugeots for a long

time, and treasure the 504 GL that's

part of my garage. I'd been tempted by several 203s, 403s and 404s over

the decades, but never found one that ticked the boxes for me. Until,

that is, I put feelers out on Facebook groups for owners to submit

alternative cars to a Fiat 1100D I was contemplating a the time.

One response, from the Sunshine Coast in

Queensland, was this 403B that had been owned long term by its

enthusiastic owner. After a lot of communication back and forth, and

many detailed photographs, I took the plunge and drove the trusty Isuzu

beavertail on the almost 4000km return trip to pick up the car.

It had been suggested by the seller that I drive

the car back, but I am glad I didn't do that, as many issues presented

themselves once I got the car home, taken for a short initial test

drive, and then put on the hoist for some urgent work to contaminated,

grabby brakes, and to investigate noisy differential bearings (a rebuild

will be in order soon, but the thick, creamy, gooey mess that finally

oozed from the final drive when drained was the worst I've seen in 50

years or working on cars).

Many other aspects needed to be attended to

straight away, and even things like maladjusted tappets (insufficient

clearance starting to cause burnt valves), leaky tappet cover gasket,

badly fitted headlights with chrome trim rings not screwed on and myriad

other things would have made the long drive very testing for both car

and driver. Cosseting it on the back of the Isuzu was definitely the

right call!

That said, the 403B will be a much-loved family

member once the issues are all sorted. It's a beautifully straight and

largely rust-free body, and the original upholstery still looks lovely,

with just the right amount of ageing. The widened rims make it much

easier to purchase tyres when the time comes, and it drives and steers

surprisingly well on them. It's lovely to have another Pininfarina

designed Pug! The search for a nice 203 and 404 continues...

↑After a long drive

from Victoria to Queensland, the Peugeot is loaded onto the trusty truck

for its trip to its new home./p>

↑The first of several

overnight stops on the return journey. This one in Warwick, Qld.

↑The Peugeot meets

another French garagemate in the workshop.

↑Safely in its new

home, but plenty of disappointments to show themselves and require

attention...

↑The car had been described as

being built from a completely rust-free body, but this was slightly

untrue, as a view from underneath quickly showed.

↑The car had been described as

being built from a completely rust-free body, but this was slightly

untrue, as a view from underneath quickly showed.These areas

were cut out and MIG welded. Still, for a 403 body, it was pretty

good.

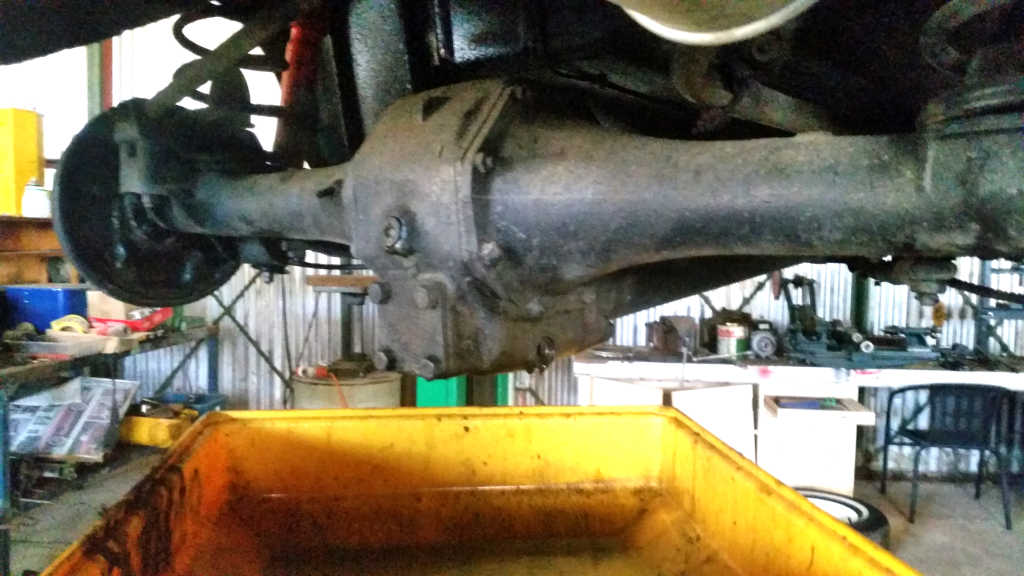

↑A

short test drive before putting it on the hoist showed that the diff

was quite noisy. Not a whine, but lots of 'white noise' that indicated

to me the worm bearings were probably suspect. Draining the oil was

quite depressing, as the most horrible, thick (treacle-like), emulsion

slowly oozed from the drain. Who knows what 'lubricants' had been put

in there, along with obvious water ingress at some stage.

↑So, the just-fitted

towbar proved perfect for lifting the rear of the car, using the forklift, high

enough - while still on the hoist - to remove the back axle as a unit...

↑...and roll it out onto

the workshop floor.

The

axle was a complete mess. The torque tube was full of a mixture of

grease, gearbox oil and water I took days to completely disassemble,

and, using strong solvents, a pressure washer, and lots of elbow grease,

finally have it all stripped down to assess what what going on.

Strangely, no photos were taken during this time!

↑The

rear gearbox seal, extricated once the front universal was removed,

was virtually new, but incorrectly fitted, and the wrong size! The

seal number clearly showed it was incorrect, as the inner lip had an

internal diameter 1 mm LARGER than the shaft it was supposed to seal.

Therefore, the gearbox simply leaked profusely, down through the

torque tube (with all its grease for the centre bearing) and then

entered the differential via the completely hardened and worn worm

seal to simply fill the differential with the completely wrong oil.

The levels got so high (along with water that must have entered via

the breathers in floodwater or creek crossings) that the muck was

oozing all over the newly replaced rear brake shoes, rendering them

useless.

↑The

crownwheel confirmed the claim that the car's mechanicals had done

very little mileage since new, as there was very little actual wear on

the teeth. However, the severe pitting on the drive side showed

exactly what the sulphur in the incorrect lubricant does to the bronze

gears; extreme chemical attack and subsequent cavitation. The bottom

of the diff housing had lots of small particles of bronze, all from

the pitted gears. After much measuring, consultation with various

experts, and my own research, I decided that the crown wheel would be

pressed back into service, but only after rebuilding the internals

(new thrust washers, bearings, and high-tensile bolts), and I also

decided, against the advice of some, to reverse the crown wheel so

fresh bronze faces would be the drive side, and the pitted areas on

the lighter-loaded overrun side. I decided this because the gears are

symmetrical, and with very accurate shimming and setting of position

(relative to the worm) and preload, there should be no reason for the

diff to whine or hum, as it had never done so before. The new bearings

- particularly on the worm, but I replaced them all just to be safe -

should address the 'white noise' I'd heard from the diff previously.

↑The worm, once cleaned up, was

pristine, so I simply pressed new bearings onto it.

↑The worm, once cleaned up, was

pristine, so I simply pressed new bearings onto it.

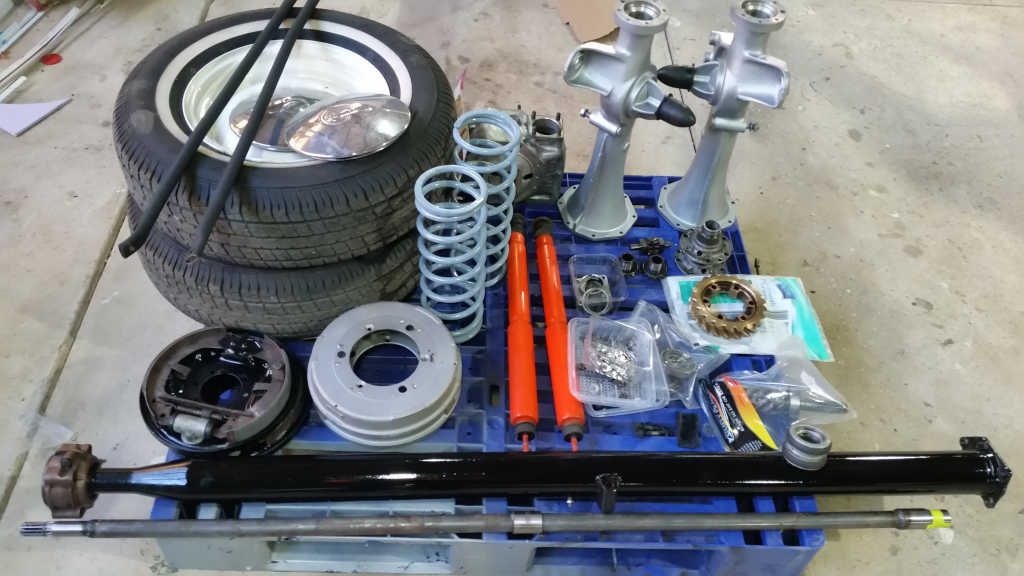

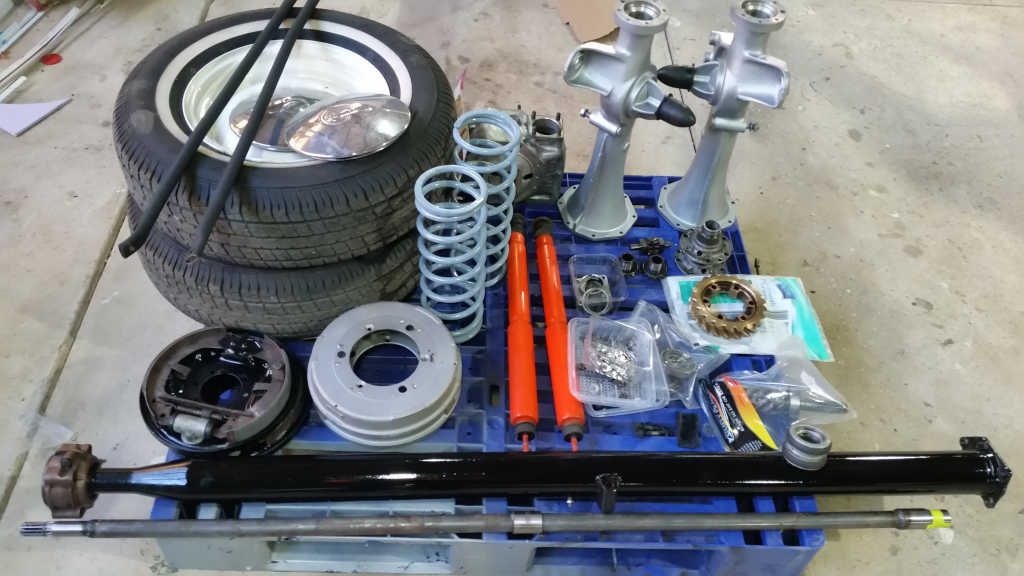

↑Here are the rear axle

components all cleaned, restored or replaces as necessary, and ready for

reassembly.

↑Here are the rear axle

components all cleaned, restored or replaces as necessary, and ready for

reassembly.

↑Reassembled and ready for

installation.

↑Reassembled and ready for

installation.

↑Ready and waiting!

↑Ready and waiting!

↑Ready to go, and filled with

the correct Castor-based Castrol R40 oil.

↑Ready to go, and filled with

the correct Castor-based Castrol R40 oil.

↑Not

only the rear brakes, recently replaced by the previous owner, had to

have new linings installed. Leaky brakes all round had saturated the

front linings as well, as can be seen even looking under the car at

the damp sections at the bottom of the backing plate. I rebuilt all

the slave cylinders, installed brand new brake shoes all around, and

replaced some corroded brake lines with new ones I made up myself in

the workshop, all correctly flared. This car should never have

recently passed its Queensland registration inspection as it was.

↑When I purchased the car, I was

pleased to see it had been fitted with all new body rubbers. However, I

was dismayed to notice that when water was sprayed on the car it sprayed

straight into the interior; none of the rubbers was correct, or sealing

in any way. I had to remove them all (they'd been horribly stuck on, so

it was hours and hours of painstaking work trying not to damage the

bodywork or paintwork underneath), and throw them all away and start

again.

↑When I purchased the car, I was

pleased to see it had been fitted with all new body rubbers. However, I

was dismayed to notice that when water was sprayed on the car it sprayed

straight into the interior; none of the rubbers was correct, or sealing

in any way. I had to remove them all (they'd been horribly stuck on, so

it was hours and hours of painstaking work trying not to damage the

bodywork or paintwork underneath), and throw them all away and start

again.

The

car is now nice and watertight, and free of wind (and diff) noise!

↑Now

reassembled, and fitted with its towbar, mudflaps and original front

sunvisor, the car drives as well as it looks!